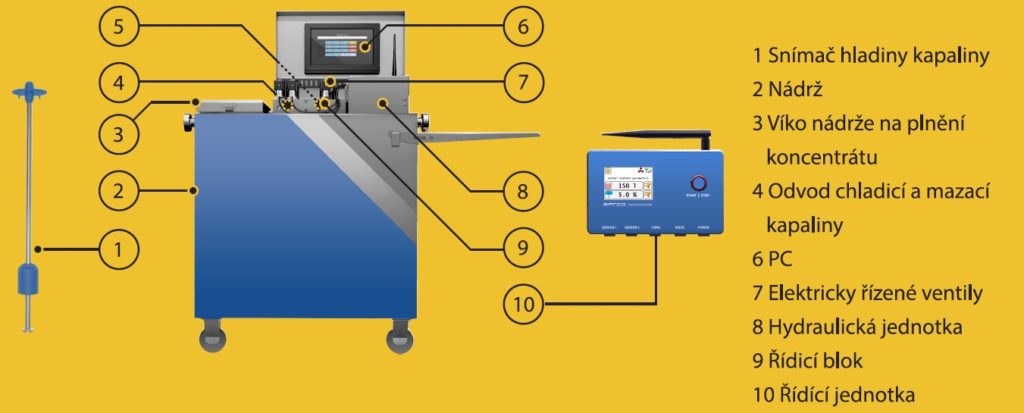

UST-100

- Cooling and lubricating fluid (CHMK)

- CHMK plays an important role in metal machining

- A stable CHMK concentration means:

- long service life of the cutting tool

- equipment protection

- high quality of manufactured parts

- Precise, programmable and automated mixing of liquids with water (including CHMK)

- Long service life of cutting tools, anti-corrosion protection of equipment and manufactured parts made of metal and alloys

- Convenient and easy operation, increased production productivity

- Main advantages:

- Automation of the process of mixing, feeding and checking the CHMK level

- Convenient and easy to use

- Possibility to connect up to 30 machines simultaneously

- ZigBee wireless technology is used to exchange data

- The station does not need a pump for its operation

- High reliability and long service life

- What does it take to work?

- Water pressure in the pipeline (1.5…10 Bar)

- AC supply ~220V or DC supply = 24V

- Control

- Control of the cooling and lubricating fluid production process is ensured using the special WasserMix Software. There are two options:

- touch screen panel on the lid of the UST-100 device

- Remote Access

- Control of the cooling and lubricating fluid production process is ensured using the special WasserMix Software. There are two options:

- The device allows you to control up to 30 machines in a row with different concentrations of KSS

Detailed information about the device can be found here.

Contact person

- Libor Holba

- Tel.: +420 577 330 208 kl. 34

- e-mail: hli@peform.com